Numerical Investigation of The Effect of Fin Thickness on Straight Fin Heat Sink on Heat Transfer Performance

DOI:

https://doi.org/10.36499/jim.v21i1.12682Keywords:

Heat sink, SFHS, Straight finAbstract

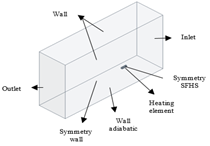

The heat load on computer chips during computing performance is the main topic, so a cooling device is needed. Heat sink is one of the tools commonly applied to reduce the heat load during computing performance of computer systems. Various heat sink configurations have been widely developed and studied to obtain designs with the best thermal performance. This research was conducted to investigate the best design on a straight fin heat sink (SFHS) that has the best thermal and hydraulic performance. SFHS with fin thickness variations of 1 mm, 2 mm, and 3 mm are proposed in this study. The numerical method was carried out using the Computational Flui Dynamics program by considering fluid flow velocities of 4 m/s, 6 m/s, 8 m/s and 10 m/s. The numerical results show that the cooling rate of SFHS can be increased by using SFHS with a thickness of 3 mm and a fluid flow velocity of 10 m/s with a maximum Nusselt number value of 59.74. Therefore, it is concluded that the SFHS has prospects for further study and can be applied practically in the field for micro electronic components and computer systems.

Keywords: Heat sink, SFHS, Straight fin.

References

Yifan L., Congzhe Z., Guodong X., (2025). Experimental investigation on the Phase Change Liquid Cooling Characteristics in the Offset Grooved Microchannel Heat Sink. Applied Thermal Engineering. 269(1), 1-14.

Sherin. M., Gaosheng. W., Hoosam A. M. El-Hamid., (2025) Multi-Objective Optimization of Grooved Circular Pin-Finned Heat Sink with Phase Change Material. Applied Thermal Engineering. 262(2), 1-12.

John. S. S., Ravikiran C., Bridjesh. P., Seshibe M., (2025). Novel Design of Serpentine Channel Heat Sinks with Rectangular and Triangular Ribs and Grooves for 25Ah Li-Ion Battery Thermal Management. International Journal of Thermofluids. 25(1), 1-18.

Yongrui. B., Zhen. C., Zhenzhou. L., Yuxiang L., Yuetong L., Xu Lu., Ding Y., Zhenfei F., (2025). Experimental Investigation on the Effects of Inclined Grooves on Flow Boiling Heat Transfer and Instability in a Minichannel Heat Sink. International Journal of Heat and Mass Transfer. 236(2), 1-13.

Safi’i, M., Sinaga, N., Syaiful, & Sukiman. (2022). Computational Study of the Effect of Fin Longitudinal Spacing and Reynolds Number on the Performance of Oblique Heat Sinks. International Research Journal of Innovations in Engineering and Technology (IRJIET), 6(9), 27-38.

Safi'i, M., Sinaga, N., Priangkoso, T., Susanto, S., & Digdoyo, A. (2024). Investigasi Model Numerik pada Simulasi Heat Sink Sirip Lurus Dengan Memvariasikan Jumlah Grid, Model Viscous dan Metode Pemecahan dengan Pendinginan Konveksi Bebas. Jurnal Ilmiah Momentum, 20(1), 31-41.

Huang. C. H and Chen W. Y., (2022). A Natural Convection Horizontal Straight-Fin Heat Sink Design Problem To Enhance Heat Dissipation Performance. International Journal Thermal Science, 176(2), 1-13.

Moradikazerouni. A, Afrand. M, Alsarraf. J, Wongwises. S, Asadi. A, and Nguyen. T. K. (2019). Investigation of a Computer CPU Heat Sink Under Laminar Forced Convection using a Structural Stability Method. International Journal Heat and Mass Transfer. 134(3), 1218–1226.

Pan. M, Chen. Z, and Li C. (2021). Experiment and Simulation analysis of Oriented Cut Copper Fibre Heat Sink for LED Water Cooling,” Case Study Thermal Engineering. 24(4), 1- 17.

Mohamed. H., Roberta. P., Ahmed E., Jason D., Roger K., (205) A Lightweight Additively Manufactured Two-Phase Integrated Natural Convection Heat Sink. Applied Thermal Engineering.

Hussein S. S., Khalid B. Saleem., Badr. M. A., Mohamed T., Abdelkarim A., Lioua K., (2024). Numerical Investigation of Natural Convection From a Horizontal Heat Sink with an Array of Rectangular Fins. Case Studies in Thermal Engineering. 61(4), 1-16.

Ishtiaque H. M. D., Samiul H. C., Syed S. U. Ahmed., Abu Hamja., Istiaq J. S., (2025). Forced Convective Heat Transfer Over Twisted and Perforated Forked Pin Fin Heat Sink: a Numerical Study. International Journal of Thermal Sciences. 211(1), 1-15.

Alihosseini. Y., Targhi. M. Z., and Heyhat. M. H., (2020). Thermohydraulic Performance of Wavy Microchannel Heat Sink with Oblique Grooved Finned. Applied Thermal Engineering. 189(2), 1-11.

Song. J. G., Lee. J. H., and Park. I. S., (2021). Enhancement of the cooling Performance of Naval Combat Management System using Heat Pipe. Applied Thermal Engineering. 188(2), 1-12.

Alihosseini. Y., Targhi. M. Z,, and Heyhat. M. H., (2020). Thermohydraulic Performance of Wavy Microchannel Heat Sink with Oblique Grooved Finned. Applied Thermal Engineering. 189(2), 1-11.

Kanargi. B., Tan. J. M. S., Lee. P. S., and Yap. C., (2020). A Tapered Inlet/Outlet Flow Manifold for Planar, Air-Cooled Oblique Finned Heat Sinks. Applied Thermal Engineering. 174(1), 1-18.

Ehtesham. A., Sajan T., Jaehyun. P., Jaemun. C., Jaehun. C., Chanwoo. P., Hesung. P., (2024). A Novel Spiral Grooved Cooling Path Heat Sink for the Cooling of High Voltage Direct Current Devices. International Journal of Thermal Sciences. 195(3), 1-16.

Anas. A., Fadi. A., Bobby. M., (2024). Characterization of MEMS Heat Sinks Having Straight Microchannels Integrating Square Pin-Fins for Liquid Cooling of Microelectronic Chips. Thermal Science and Engineering Progress. 45(4), 1-15.

Refaey. H. A., Mathkar A. A., Samir. B., Said. G. K., Mohamed. E., Abdelrahman. M. A., (2023). An Experimental Investigation on Passive Cooling of a Triple-Junction Solar Cell at High Concentrations Using Various Straight-Finned Heat Sink Configurations. Case Studies in Thermal Engineering. 51(2), 1-17.

Nedal. O. E. S., Fadi. A., Bee. T. C., Bobby. M., (2025). Performance Evaluation of MEMS Heat Sinks Having Straight Microchannels Integrating Rectangular Sidewall Cavities in In-Line Pattern. Applied Thermal Engineering. 266(1), 1-16.

Jin. Y., Yongfeng. Q., Ningkang. D., Liang. D., Wenbo. H., Xiaofan. Z., Shengli. W., Hongxing. W., (2023). Three-Dimensional Numerical Investigation of Flow and Heat Transfer Performances of Novel Straight Microchannel Heat Sinks. Diamond and Related Materials. 140(1), 1-18.

Jianlei. C., Haozhe. K., Jian. D., Xiangyang. D., Zhijun. W., Zhengjie. F., Wenjun. W., Xuesong. M., (2024). High-Quality Fabrication of Diamond Straight Microchannels Heat Sink with Large Aspect Ratio Microchannels using UV Nanosecond Laser Based On Multi-Feed Method. Optics & Laser Technology. 171(2), 1-18.

Adhikari. R. C., Wood. D. H., Pahlevani. M., (2020). An Experimental and Numerical Study of Forced Convection Heat Transfer from Rectangular Fins at Low Reynolds Numbers. International Journal of Heat and Mass Transfer. 163(3), 1-12.

Downloads

Published

How to Cite

Issue

Section

License

This work is licensed under a Creative Commons Attribution 4.0 International License.

Authors who publish with this journal agree to the following terms:

The journal allow the authors to hold the copyright without restrictions and allow the authors to retain publishing rights without restrictions.

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgement of its initial publication in this journal.

Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See The Effect of Open Access).

This work is licensed under a Creative Commons Attribution 4.0 International License.