Pengaruh Pack Carburizing Arang Enceng Gondok terhadap Laju Korosi Cast Iron Alat Turbocharger

DOI:

https://doi.org/10.36499/jim.v21i1.12668Keywords:

pack carburizing, water hyacinth charcoal, cast iron, corrosion resistance, mechanical propertiesAbstract

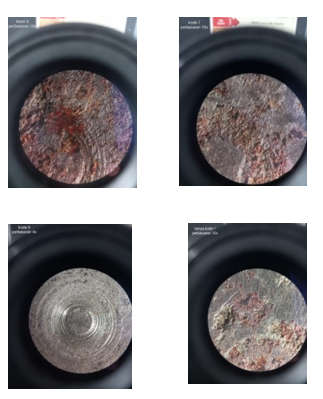

Corrosion resistance is a crucial factor in extending the service life of cast iron turbocharger components, particularly in corrosive environments. One effective approach to enhance corrosion resistance is through the pack carburizing process, which forms a protective carbon layer on the material’s surface. In this study, water hyacinth charcoal was utilized as an alternative carbon source due to its environmentally friendly and economical characteristics. The research aimed to evaluate the effect of varying pack carburizing durations on the corrosion resistance of cast iron turbochargers and to characterize the macrostructural changes on the surface resulting from the treatment. The methodology involved a pack carburizing process with holding times of 2, 4, and 6 hours at a controlled temperature, followed by electrochemical corrosion testing. Macrostructural characterization was also conducted to observe surface morphology changes due to carbon diffusion. The test results showed that the untreated specimen had a corrosion rate of 0.180 mm/y, which decreased to 0.120 mm/y after 2 hours of carburizing. A more significant reduction was observed in the 4-hour specimen, with a corrosion rate of 0.095 mm/y, representing a 47% decrease compared to the untreated sample. However, after 6 hours, the corrosion rate only slightly decreased to 0.090 mm/y, indicating that the carbon layer had reached saturation. Macrostructural observations confirmed the formation of a more homogeneous carbon layer in the 4-hour specimen, while the 6-hour specimen exhibited a thicker layer with diminishing protective effectiveness. This study demonstrates that pack carburizing using water hyacinth charcoal can significantly enhance the corrosion resistance of cast iron turbochargers, with an optimal treatment duration of 4 hours for maximum protection.

Keywords: pack carburizing, water hyacinth charcoal, cast iron, corrosion resistance, mechanical properties

References

Asri, M., et al. (2020). Effect of biomass-based carburizing on steelproperties. Materials Science

Forum, 987, 123130.

Callister, W.D., & Rethwisch, D.G. (2020). Materials Science and Engineering: An Introduction

(10th ed.). Hoboken: John Wiley & Sons.

Gupta, R., & Singh, A. (2022). Corrosion resistance of carburized steels. Surface and Coatings

Technology, 432, 128-137.

Jaya, A., & Fitriani, D. (2023). Enceng gondok as alternative carbon source. Journal of Renewable

Biomass, 12(3), 45-53.

Jaya, A., & Fitriani, D. (2023). Pengaruh Media Karbon Berbasis Biomassa terhadap Efisiensi Proses

Karburisasi Padat pada Baja Karbon Rendah. Jurnal Teknologi dan Aplikasi Material, 15(2),

77–84.

Jaya, A., & Fitriani, R. (2023). Utilization of Biomass-Based Carbon Media for Surface Hardening

and Corrosion Resistance Enhancement of Cast Iron. Indonesian Journal of Mechanical

Engineering, 15(2), 89-97.

Siregar, A., et al. (2020). Carburizing kinetics on iron alloys. Metallurgical Transactions A, 51(3),

456-467.

Wang, T., et al. (2021). Surface hardening of cast iron. International Journal of Cast Metals

Research, 34(5), 298-306.

Wang, X., Li, Y., Zhang, T., & Chen, H. (2020). Effect of Carburizing Treatment on Corrosion

Resistance of Cast Iron in Electrochemical Environment. Journal of Materials Science &

Technology, 36(5), 1023-1032.

Wang, X., Li, Z., & Zhou, Y. (2020). Effect of Carbonized Layer from Pack Carburizing on the

Corrosion Resistance of Grey Cast Iron. Journal of Surface Engineering and Applied

Electrochemistry, 56(3), 291–298.

Zhang, L., & Wang, Y. (2021). Sustainable carburizing using agricultural waste. Journal of

Materials Processing Technology, 293,117035.

Downloads

Published

How to Cite

Issue

Section

License

This work is licensed under a Creative Commons Attribution 4.0 International License.

Authors who publish with this journal agree to the following terms:

The journal allow the authors to hold the copyright without restrictions and allow the authors to retain publishing rights without restrictions.

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgement of its initial publication in this journal.

Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See The Effect of Open Access).

This work is licensed under a Creative Commons Attribution 4.0 International License.