Studi Numerik Pengaruh Variasi Longitudinal dan Transversal Pitch terhadap Performa Fin and Tube Heat Exchanger

DOI:

https://doi.org/10.36499/jim.v20i2.11945Keywords:

Kata kunci, Fin and Tube Heat Exchanger, Longitudinal Pitch, Transversal Pitch, Performa.Abstract

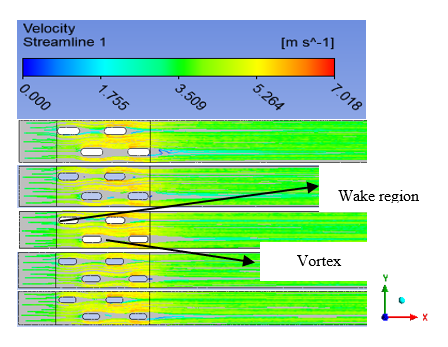

Fin and tube heat exchanger (FTHE) banyak digunakan dalam sistem pendingin, petrokimia, dan aplikasi HVAC&R karena pembuatannya lebih mudah, konstruksinya sederhana, rendah biaya, dan relatif mudah dalam perawatan menjadikannya salah satu yang paling umum digunakan. Peningkatan kebaikan perpindahan panas pada FTHE telah banyak di investigasi guna untuk meningkatkan performanya. Riset ini dilakukan untuk mengetahui pengaruh variasi rasio arah longitudinal dan transversal pitch pada FTHE terhadap performa termalnya dengan menggunakan aplikasi Fluent pada program komputer Computational Fluid Dynamics. 2 variasi desain FTHE berupa rasio arah longitudinal dan arah transversal pitch di berbagai variasi kecepatan aliran fluida dengan heat flux konstan sebesar 100 W diusulkan. Hasil terbaik riset ini di dapatkan bahwa variasi rasio arah longitudinal pitch 14,5 mm dengan nilai koefisien perpindahan panas sebesar 97,24 W/m²K, sedangkan rasio arah transversal pitch 11,7 mm dengan nilai koefisien perpindahan panas sebesar 107,82 W/m²K. Hasil tersebut mengkonfirmasi bahwa variasi rasio arah longitudinal pitch 14,5 mm dan transversal pitch 11,7 mm dapat digunakan dan diterapkan untuk aplikasi praktis pada FTHE. Desain tersebut juga memungkinkan dapat dijadikan rekomendasi untuk perancangan dan diterapkan secara langsung di lapangan.

References

A. A. Bhuiyan, A.K.M. S. Islam., (2016). “Thermal and Hydraulic Performance of Finned-Tube Heat Exchangers Under Different Flow Ranges: A Review on Modeling and Experimentâ€. International Journal of Heat and Mass Transfer, 101:38-59. http://dx.doi.org/10.1016/j.ijheatmasstransfer.2016.05.022.

A. A. Bhuiyan, M. R. Amin, A. K. M. S. Islam, (2013). “Three-Dimensional Performance Analysis of Plain Fin Tube Heat Exchangers in Transitional Regimeâ€, Applied Thermal Engineering. Vol. 50. PP. 445-454. http://dx.doi.org/10.1016/j.applthermaleng.2012.07.034.

B. Cárdenas, S.D. Garvey, B. Kantharaj, M.C. Simpson, (2017). “Gas-to-gas Heat Exchanger Design for High Performance Thermal Energy Storageâ€. Journal of Energy Storage 101, Vol. 14:3 PP. 11-321. http://dx.doi.org/10.1016/j.est.2017.03.004.

B. Masoumpour, M. Ataeizadeh, H. Hajabdollahi, M. S. Dehaj, (2021). “Performance Evaluation of a Shell and Tube Heat Exchanger with Recovery of Mass Flow Rateâ€. Journal of the Taiwan Institute of Chemical Engineers. Vol. 000. PP. 1-13. https://doi.org/10.1016/j.jtice.2021.05.022.

H. Bayat, B. Hamidreza, L. A. Mirabdolah, M. Taher, (2014), “Experimental study of thermal–hydraulic performance of cam-shaped tube bundle with staggered arrangementâ€. Energy Conversion and Management, Vol. 85 No. 2. PP.470-476. https://doi.org/10.1016/j.enconman.2014.06.009.

C. W. Lu, J. M. Huang, W.C. Nien, C. C. Wang. (2011). “A Numerical Investigation of The Geometric Effects on the Performance of Plate Finned-tube Heat Exchangerâ€, Energy Conversion and Management, Vol. 52: PP. 1638-1643. http://doi:10.1016/j.enconman.2010.10.026.

D. Taler, J. Taler, K. Wrona, (2021). “New Analytical Numerical Method for Modelling of Tube Cross Flow Heat Exchangers with Complex Flow Systemsâ€. Energy, Vol. 228 No. 120633. PP. 1-10 https://doi.org/10.1016/j.energy.2021.120633.

D. Sahel, H. Ameur, W. Boudaud, (2019). “A New Correlation for Predicting the Hydrothermal Characteristics Over Flat Tube Banksâ€. Journal of Mechanical and Energy Engineering, Vol. 3. No. (43):3. PP. 273.280. https://doi:10.30464/jmee.2019.3.3.273.

B. Hamidreza, L. A. Mirabdolah, M. Taher, (2014). “Experimental Study of Thermal Hydraulic Performance of Cam Shaped Tube Bundle With Staggered Arrangementâ€. Energy Conversion and Management, Vol. 85. PP. 470-476. http://dx.doi.org/10.1016/j.enconman.2014.06.009.

G, M. Zhang, X. Leng, N. Zhou, Y. P. Shi, L. Li. (2015). “Flow and Heat Transfer Characteristics Around Egg-shaped Tubeâ€. Journal of Hydrodynamics, Vol. 27. No. (1) PP. 76-84. https://doi:10.1016/S1001-6058(15)60458-9.

H. Nemati, S. Samivand, (2015). “Performance optimization of annular elliptical ï¬n based on thermo-geometric parametersâ€. Alexandria Engineering Journal, Vol. 54. No. -. PP. 1037-1042. http://dx.doi.org/10.1016/j.aej.2015.09.016.

M. R. Salem, M.B. Eltoukhey, R.K. Ali, K.M. Elshazly, (2018). “Experimental investigation on the Hydrothermal Performance of a Doublepipe Heat Exchanger Using Helical Tape Insertâ€, International Journal of Thermal Sciences, Vol. 124. No. 1. PP. 496-507. https://doi.org/10.1016/j.ijthermalsci.2017.10.040.

M. H. Zaidan, A. A. R. Alkumait, T. K. Ibrahim, (2018) “Assessment of Heat Transfer and Fluid Flow Characteristics Within Finned Fat Tubeâ€, Case Studies in Thermal Engineering, Vol. 12. No. 124. PP. 557-562. https://doi.org/10.1016/j.csite.2018.07.006.

M. A.M. Ali, W. M. El-Maghlany, Y. A. Eldrainy, A. Attia, (2018). “Heat Transfer Enhancement of Double Pipe Heat Exchanger Using Rotating of Variable Eccentricity Inner Pipeâ€, Alexandria Engineering Journal, Vol. 57. No. 1110. PP. 3709-3725. https://doi.org/10.1016/j.aej.2018.03.003.

Downloads

Published

How to Cite

Issue

Section

License

This work is licensed under a Creative Commons Attribution 4.0 International License.

Authors who publish with this journal agree to the following terms:

The journal allow the authors to hold the copyright without restrictions and allow the authors to retain publishing rights without restrictions.

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgement of its initial publication in this journal.

Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See The Effect of Open Access).

This work is licensed under a Creative Commons Attribution 4.0 International License.